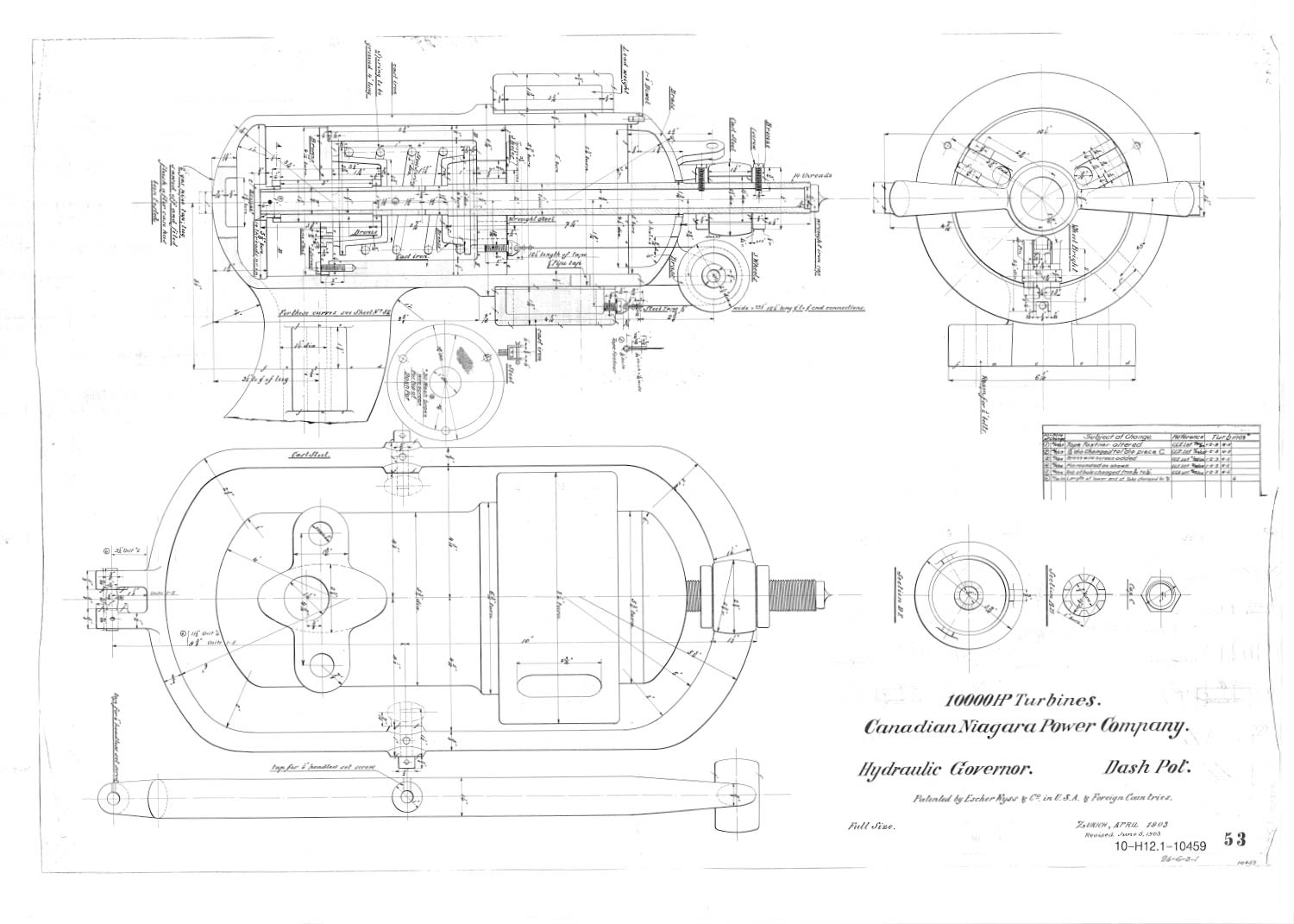

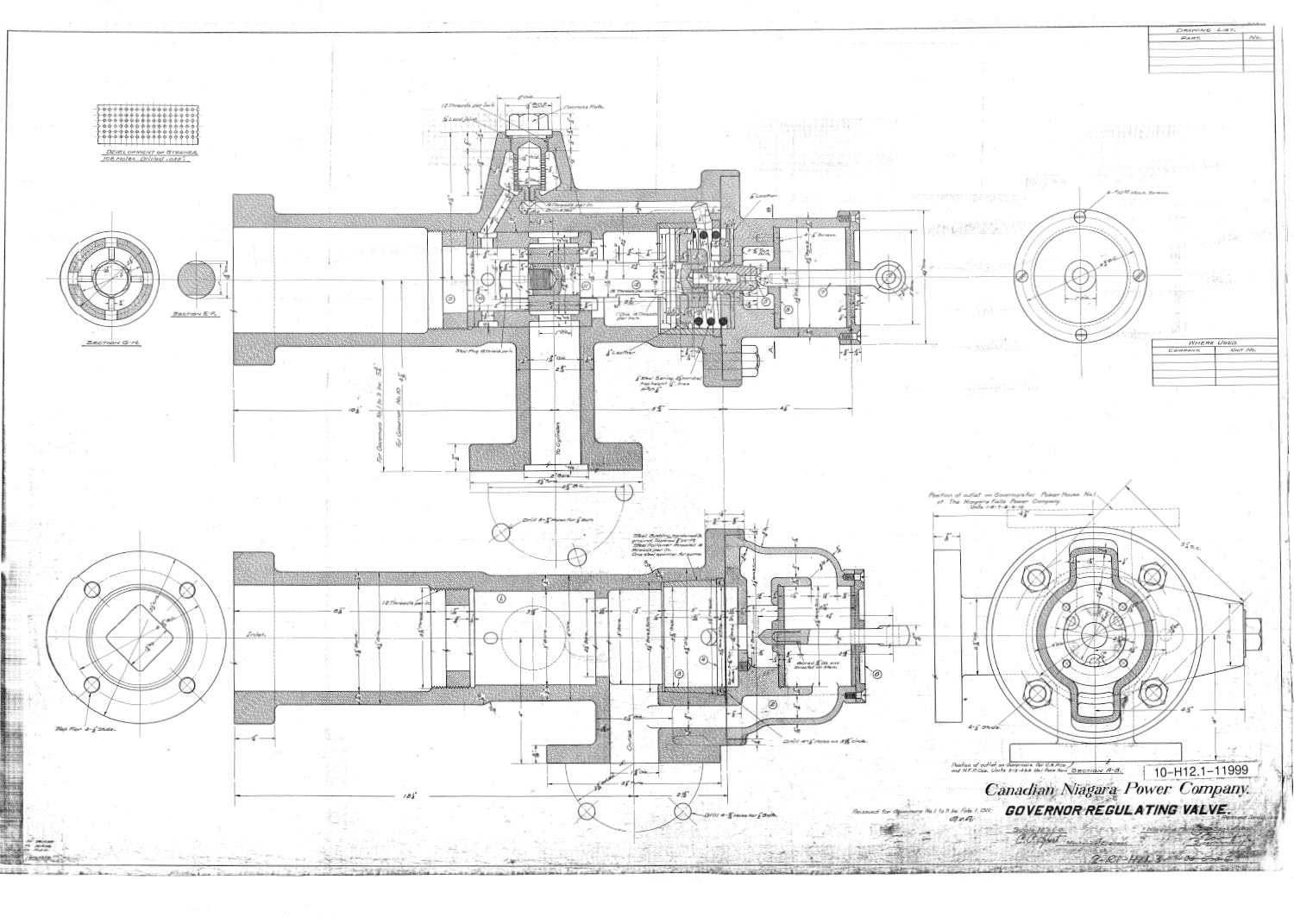

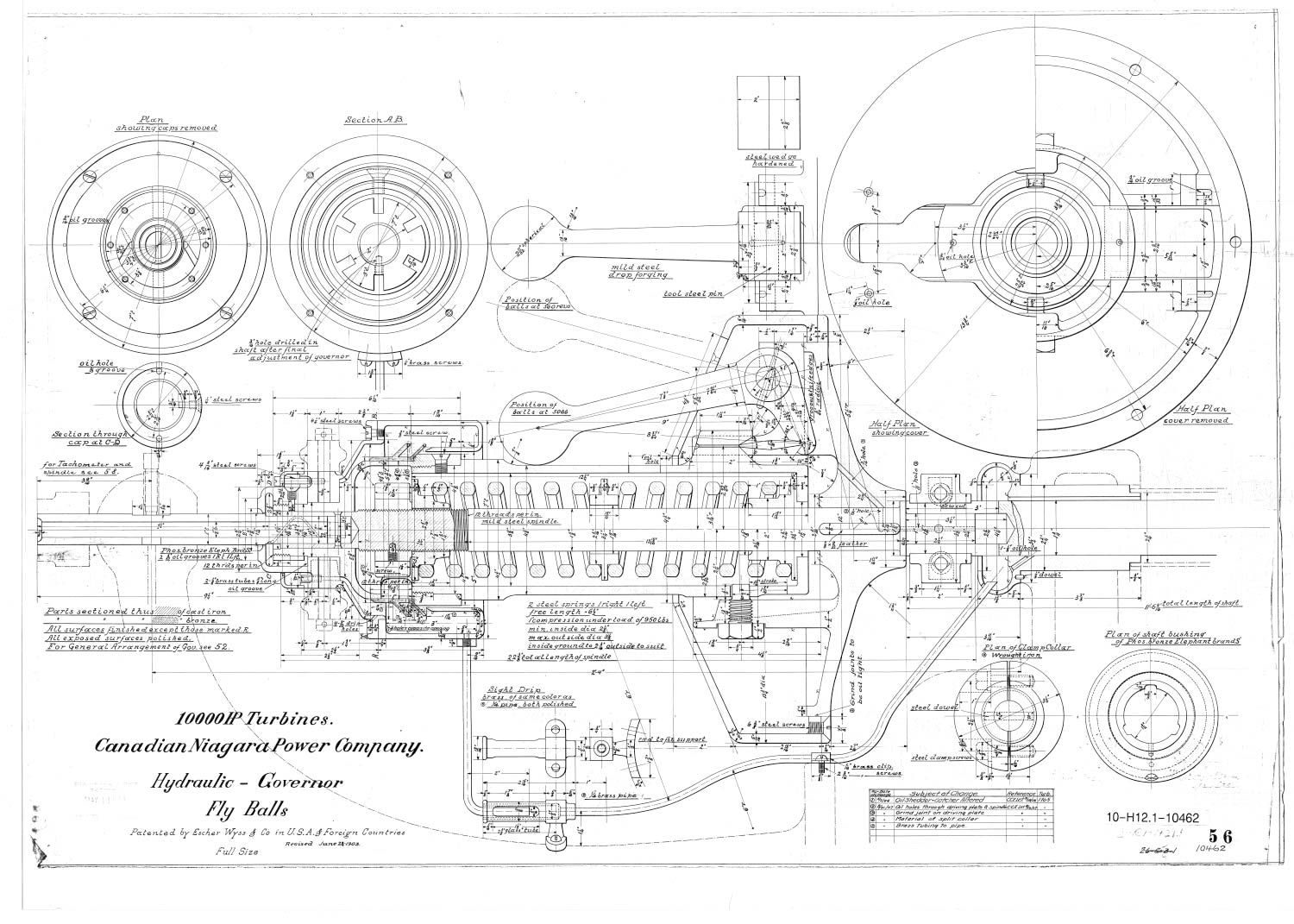

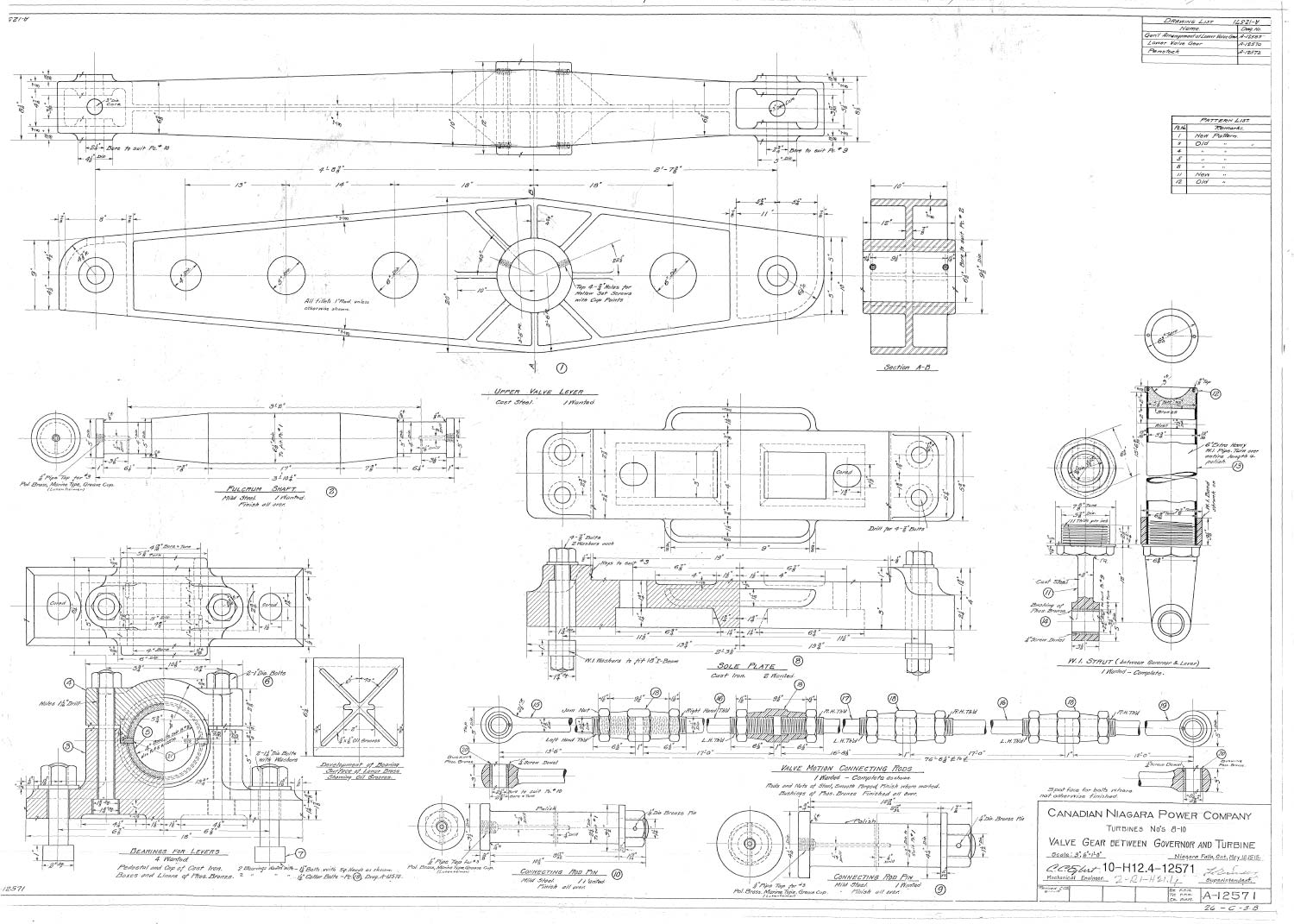

Governors

The power station’s governors, located on the generator floor, maintained a constant turbine speed. It was important to control the speed of the turbines so that electricity generated in the plant could be transmitted onto the electrical grid without incident.

Generally, hydraulic governors are more expensive than electrical or mechanical governors, but are considered to be the best as they are the quickest acting, the most sensitive and the most accurate. This power station has mechanical governors with varying designs that reflect changes in technology over time.

All 11 governors in the power station were designed and built by the Escher, Wyss & Company based in Switzerland. During the 1990s, they were replaced with computer-controlled systems. These systems rarely ran as smoothly as the manually operated governors and caused more wear and tear on the shafts and bearings than their predecessors. Workers often compared the original machinery to finely crafted Swiss watches!