Oil switches

What they do

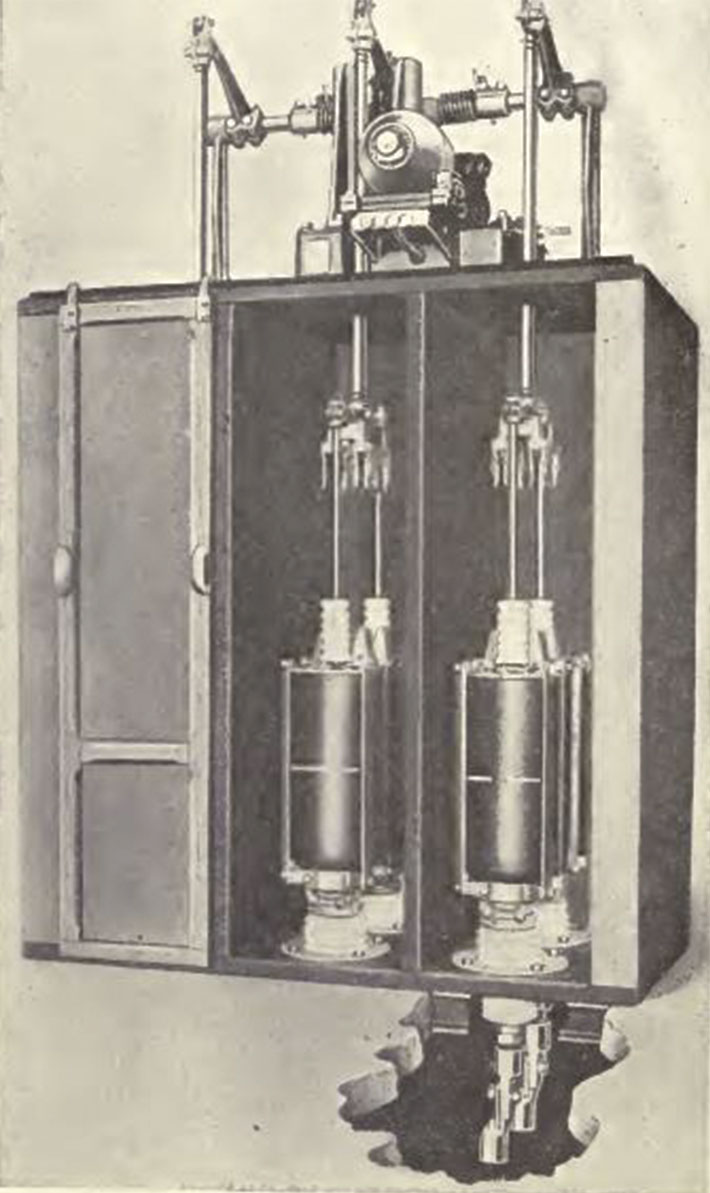

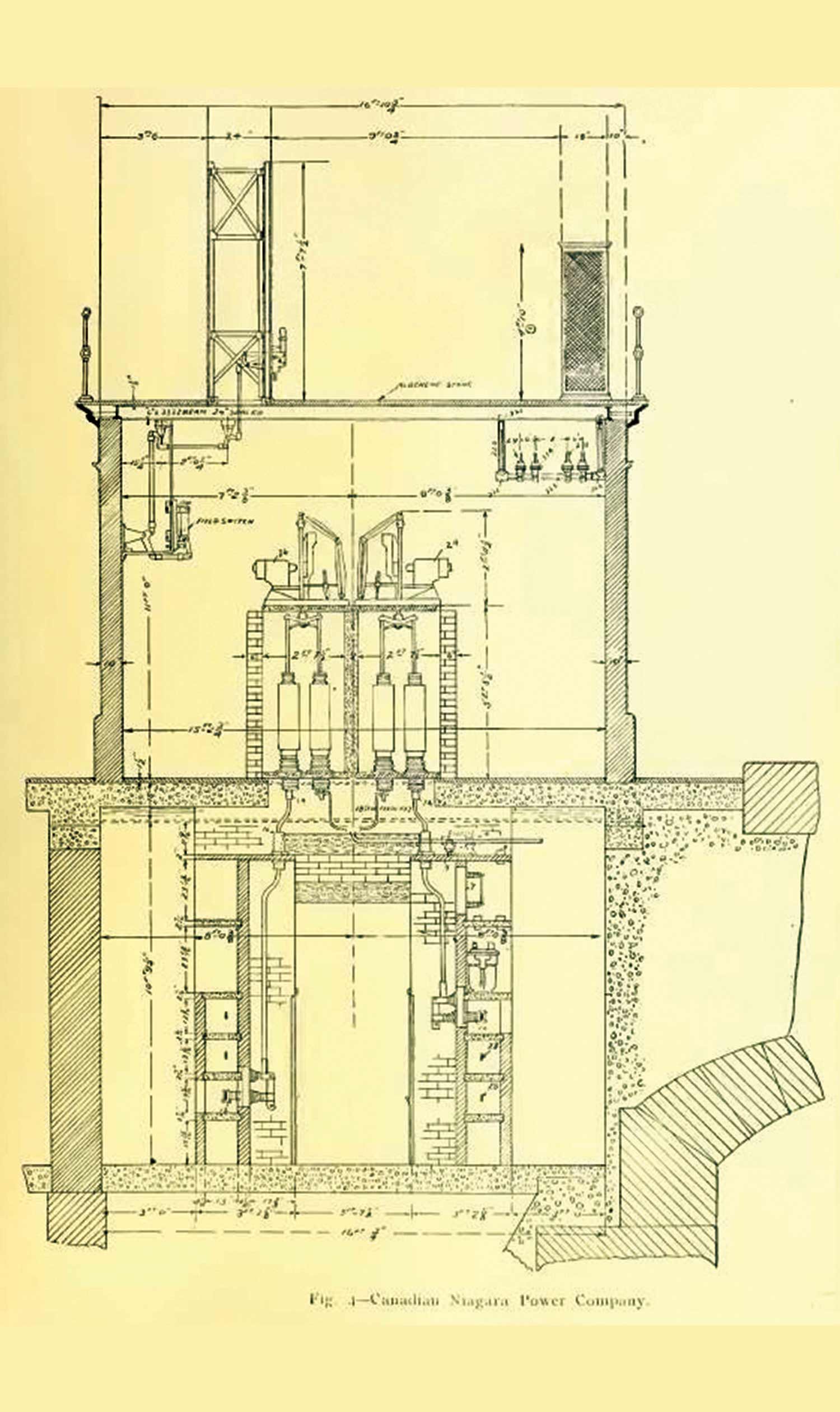

The power station’s oil switches connected the electricity produced in the generators to the transmission grid via bus bars beneath the generating floor. Similar to a subway system, the bus bars extended the full length of the power station and routed the electricity to the grid outside. The oil switch tanks safely opened and closed high voltage circuits during generating cycles as consumer demand for power fluctuated over the course of a day.

The oil switch cabinet was one of the most dangerous and unpredictable areas in the power station. To minimize the risks, each switch was contained in its own chamber built of multiple layers of protection against fire and explosions to limit potential damage.

Within each chamber, switch terminals were submerged in an insulating mineral oil bath to extinguish electric arcs caused by the opening and closing of a circuit. Remember, an electric arc is generated when an electric current jumps, or arcs, in the air between the two conductors. The process of opening and closing high voltage circuits was extremely dangerous and had to be completed within 0.02 seconds.

The oil switches were kept isolated in a room separate from the rest of the generating equipment on the main floor when the power station first opened.

How they work

To close an oil switch, the motorized mechanism at the top of the cabinet dropped down and pressed against fixed brass rods on the cylinder. As the mechanism made larger surface contact with the cylinder, switch terminals connected to the brass rods submerged under oil inside the cylinder. The closed terminals allowed electrical current to flow through the circuit.

To open an oil switch, the motorized mechanism lifted from the cylinder and released the tension on the brass rods causing the switch terminals to open. Electric arcs caused by the opening switch were suffocated by the oil in the cylinder. Extinguishing electric arcs was crucial to avoid a flammable or explosive combination of heat, fuel and air.

Resisters

In these oil switches, current flowed through a resister for a fraction of a second before the circuit closed completely. The resisters are made from metal that is not as conductive as the material normally used to carry electricity. This makes it more difficult for the electrical charges to flow through a circuit and it also controls the voltage by slowing down, or resisting, the electrons as they try to flow through the resistor. Resisters also prevent voltage spikes, protecting equipment from damage or burn out.

Modern switches

Switches used in modern hydropower stations look like the ones used here but operate differently. They are motorized and use a vacuum system inside the tank to break currents, instead of mineral oil. Modern switches with vacuum circuit breakers have minimal arcing characteristics; the arc quenches when it is stretched. These switches are frequently used to switchgear up to 40,500 volts!