Construction

Unprecedented challenges

As with most large-scale construction projects, many different contractors, companies and specialized trades were involved in the undertaking of varying aspects of this immense power plant. The intricacy and necessity of the plant’s parts to seamlessly fit and work together in such a complex way meant that most individual aspects of the construction had to proceed simultaneously.

Excavation of the wheelpit chamber, the tailrace water discharge tunnel, the cofferdam and the forebay were part of the first phase of construction that began in 1901. By 1904, preliminary construction work was finished, and all necessary electrical infrastructure had been connected. Although the powerhouse was ready to generate power by the end of that year, the plant’s generators did not operate until July 27, 1905.

Cofferdam

A large temporary cofferdam was built in the river in order to create the forebay area. The cofferdam pushed the river back so that water near the main construction site could be pumped out, leaving a dry, open space where the forebay could be excavated. Crews used pickaxes and shovels to create an expansive space in the forebay area that was 14 feet deep. The cofferdam remained in place for roughly two years.

Forebay

The forebay is where water from the Niagara River entered the power station. Water from the river was directed towards the plant by an arm-shaped weir about 1,500 feet above the falls.

The outer forebay, which filtered the incoming water through a range of underwater arches, was complemented by a bridge designed with flat steel-supported arches to provide level access for the electric railway and pedestrians. Ice racks in the inner forebay were used to prevent large chunks of ice and other debris from entering the penstocks and disrupting the plant’s operations.

During construction of the forebay, the river bottom was drilled and blasted to achieve a specific shape and depth. Workers used pickaxes and shovels to dig through sand, clay and gravel. The outer forebay runs the full length of the plant.

ACCIDENTS IN THE FOREBAY

Workers were prepared to act quickly in the rare event that someone fell into the forebay. The headgates could be controlled to either draw a fallen person in closer, or prevent them from being drawn into the penstock. A lifebuoy was also available in the inner forebay that could be thrown to assist in pulling someone out of the water.

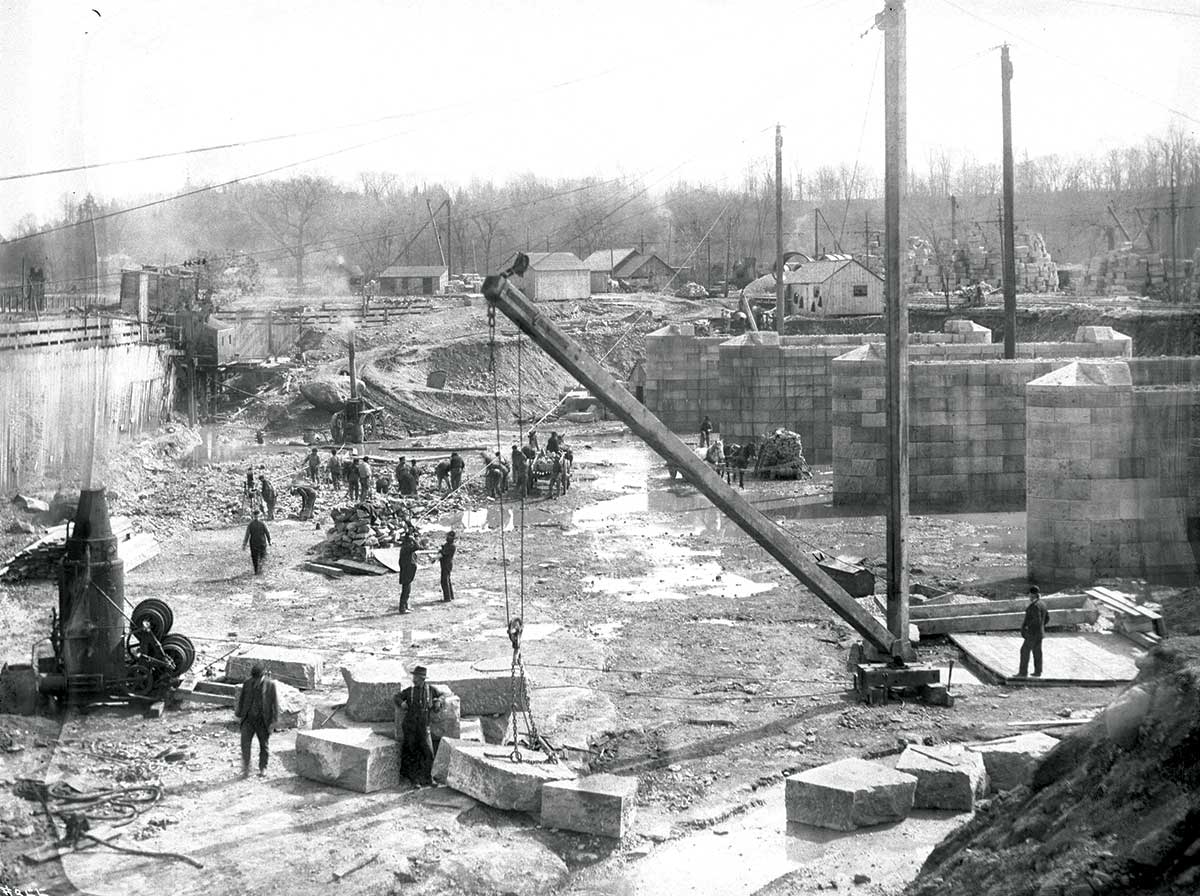

Wheelpit

The wheelpit chamber is a multi-level subterranean complex expanding 12 storeys beneath the main floor of the powerhouse. A number of important operational pieces run through this area, including the penstock pipes that carry water from the forebay down to the turbines; the long vertical driveshafts that connect each generator on the main floor to their individual turbines; and an assortment of other auxiliary equipment. The wheelpit is also connected to the tailrace tunnel.

Excavating the wheelpit was the most troublesome and demanding part of the power station’s construction. Building this great chamber was like blasting out a small quarry; the space was almost 600 feet (183 metres) long by 20 feet (6 metres) wide. Crews excavated through layers of rock and earth with dynamite, compressing drills and by hand. The debris was carried away for dumping by wagons and horses.

Once the digging was finished, the walls of the wheelpit were lined with 24 inches of brick, three layers of solid and one layer of hollow. The layer of hollow brick allowed any natural weeping from the surrounding water table to be directed down to the bottom of the pit without interfering with any of the equipment. The penstocks and other equipment were lowered into the wheelpit by overhead crane. They were lowered in pieces and assembled in place.

One of the many challenges of constructing this area was the fact that several catwalks and metal flooring grids had to be installed at various points along the solid rock walls of the wheelpit. Its beams needed to withstand the weight of other layers and decks of vital equipment. Most importantly, the top layer of support structures within the wheelpit needed to withstand the weight of the entire generating floor. The pit had to remain as structurally sound as possible; any imperfection was an invitation to water leaks, buckles or possible breaks.

OVERHEAD CRANES

Two 50-ton capacity overhead cranes would work in tandem to pick up equipment and lower it into place. These same cranes were in use since the opening of the plant and were essential during its construction. They used motors from street cars and were considered quite hard to operate.

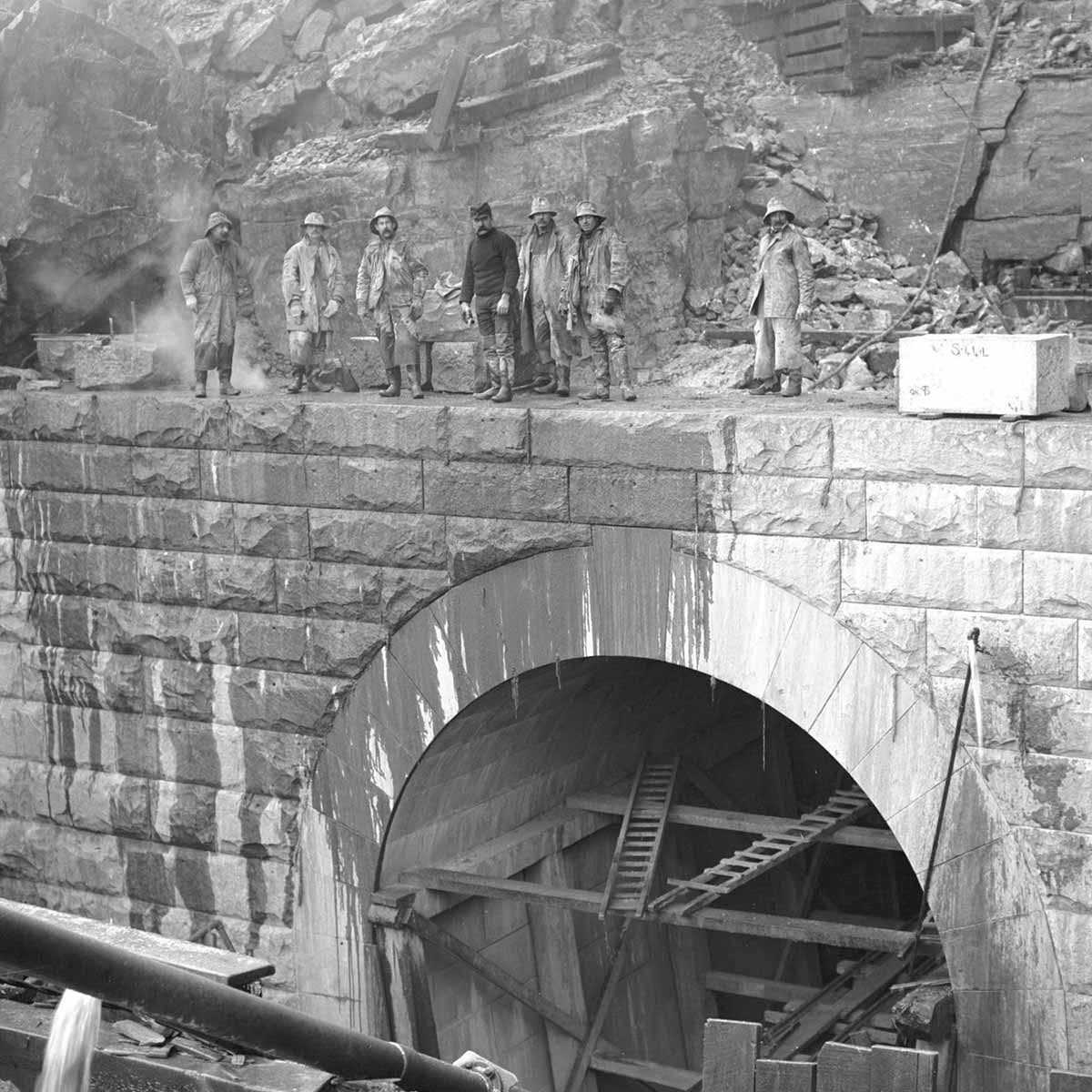

Tailrace Tunnel

The tailrace tunnel is a curving passageway that winds under the depths of the power station’s wheelpit. The water used in power station was expelled safely back to the Niagara River through the tailrace tunnel.

Construction of the 2,200-foot tunnel began by creating a vertical shaft halfway between where the tunnel connected with the powerhouse and the Niagara River. The area was blasted with dynamite and crews dug towards the plant and the river simultaneously. Building materials were lowered by derrick crane and the excavated rock was loaded into skips and lifted to the top of the gorge.

Working underground with only lanterns, rudimentary dynamite, pickaxes and shovels, crews had to somehow survey and engineer the tunnel with perfect precision. It needed to be built along a specific route with very precise dimensions and angles. There was no room for error—any small mistake could be replicated and amplified the longer the tunnel went on.

Work on the tailrace tunnel was successfully complete by December 1902.