The decks

Thrust deck

The first deck below the generator floor is called the thrust deck. It houses the thrust bearings that support up to 90 tons of equipment and keep the turbine shaft in alignment. A wide variety of large wrenches, some over three feet long, are also housed on the thrust deck. These wrenches were used to pry bolts loose when they became fused to the outer casing of the thrust bearings.

The bus bars are also located on the thrust deck. They carried electricity from one section of the plant to the next. Additional equipment found on the thrust deck include a few transformers and rheostats that assisted in activating the exciters.

Brake deck

The level below the thrust deck is the called the brake deck. This deck houses a brake drum that measures eight feet in diameter. When the headgates were closed and water was depleted in the forebay, workers activated the brakes on the brake deck to stop the turbine shafts from spinning. The shafts needed to be slowed to roughly 100 RPM before the brakes could be applied.

Unlike the brake drum of a car that expand outwards, these brakes clamped inwards, hugging the shaft and creating friction to slow the turbine’s spin. This movement converted the kinetic energy of the spinning shaft into thermal energy that dissipated as the brakes cooled; fires on the brake deck were known to occur.

The brake deck is also where the plant’s massive penstocks make a 90-degree turn toward the turbines below.

Upper and lower guide decks

The upper and lower guide decks have limited equipment and served mostly as pass-throughs. They house additional guide and radial bearings that assisted in keeping the shaft’s radial axis in alignment.

Turbine deck

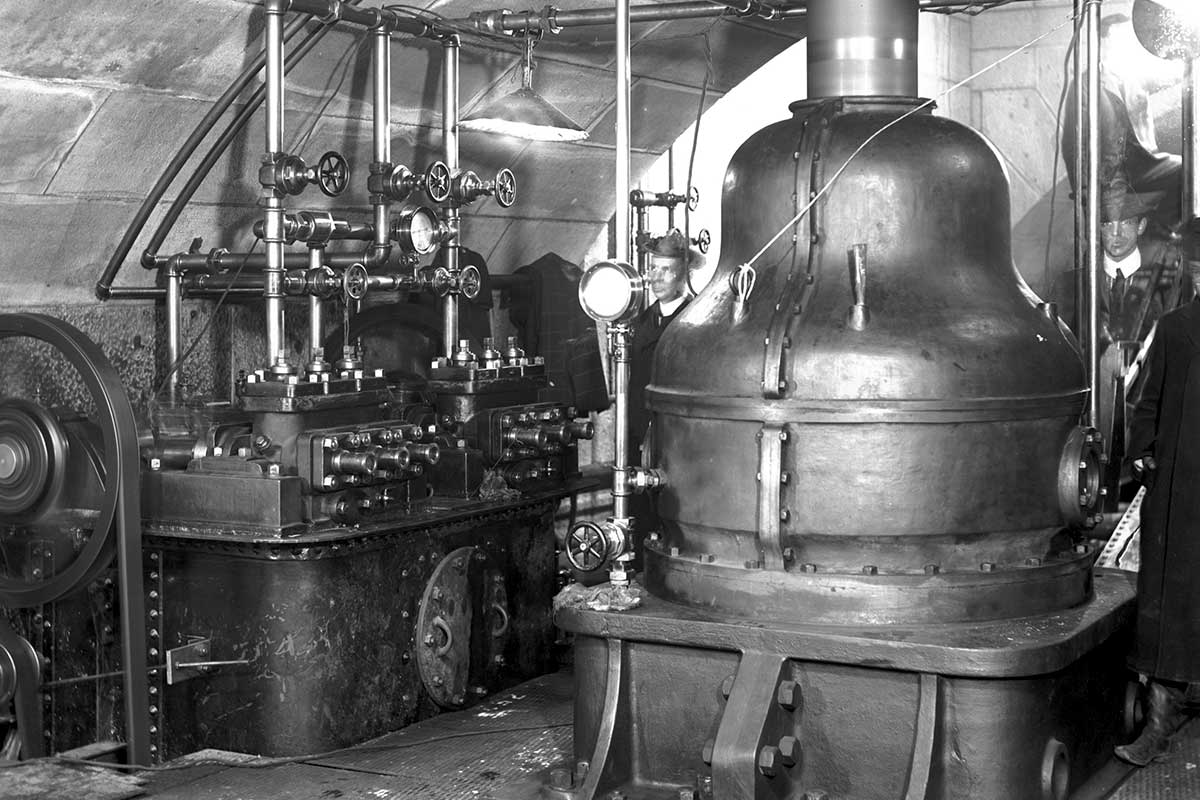

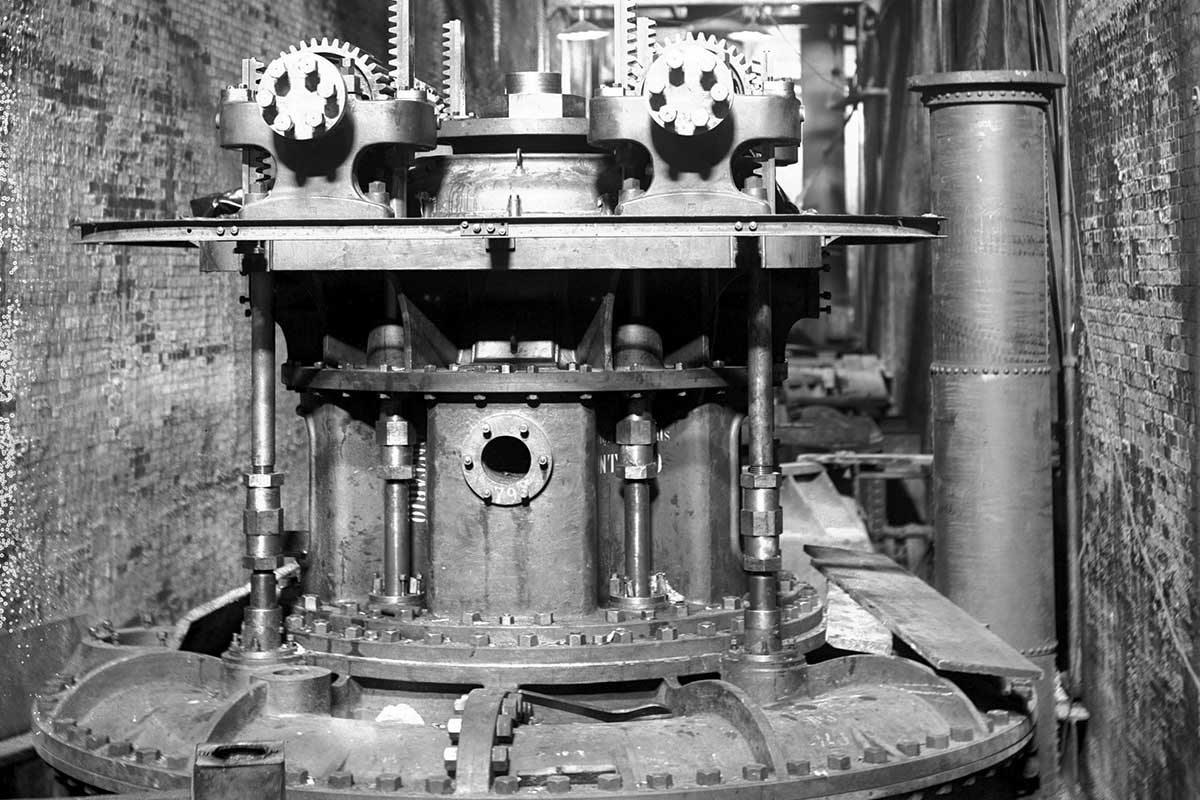

The turbine deck is beneath the upper and lower guide decks. It houses the levers and gears connected to the governors on the generating floor, and the direct valves that control the flow of water going into each turbine. Manual valve control wheels and devices to adjust the drive shaft alignment are also found on the turbine deck, in addition to smaller water and oil lines that run, bracketed, along the walls. Along the east wall, five arched chambers open into the wheelpit. These chambers were meant to hold the original water powered exciters, and their control panel.

Most of the plant’s turbine wheel casings, where water spins the turbine’s blades and drives the shaft that reaches back up to the alternators, are unseen, below the floor of the turbine deck.

Rack deck

In a few places along the turbine deck, stairs and hatches provide access down to the rack deck, a dark space with a steel grille floor. Water exiting the turbine deck above flows through here before making its way to the tailrace runnel. The rack deck is the final level above the draft chamber.

The racks were accessible from beneath generators one to five. Working on this deck was dangerous because changing water levels could shift the racks at any given moment.